Category Archive: Medical Device Packaging

Keeping Fragile Medical Devices Safe Using Solid Bleach Sulfate (SBS) Box Partitions

Medical devices as a whole often seem pretty durable, with surgical blades and stethoscopes often coming to mind first. However, many devices are actually quite fragile, such as glass pipettes and test tubes, syringes, microscope slides, and numerous other products.

From manufacturing plant to hospital, and even from hospital to research lab, these tools must sometimes travel long distances using various forms of transport. Sometimes the ride can be bumpy, and extra precautions must be taken when shipping such fragile medical components.

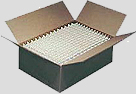

Custom manufactured Solid Bleach Sulfate (SBS) box partitions are one way to keep devices safe during transit. Each piece can be individually protected within its own section of the packaging, as seen in the image below.

These partitions can keep glass tubes from constantly shifting and bumping into each other, keeping them immobile while providing some degree of cushioning.

Incorporating layer pads into medical device packaging is another way to protect fragile instruments from damage. They provide an additional buffer between the product and the shipping container and absorb impacts from bumpy roads and rails. Anti-static layer pads also protect semiconductors and other sensitive items from damaging static electricity.

With the right packaging materials, even the most delicate tools can be shipped safely to their final destinations. For more information or to request a quote for custom medical device packaging options, feel free to contact M & M Box Partitions online.

Share this:

Posted in: Medical Device Packaging

Tags: Anti Static Layer Pads for Medical Device Packaging, Antistatic Layer Pads for Semiconductor Packaging, How to Ship Delicate Medical Devices, Keeping Semiconductors Safe from Static Electricity, Layer Pads for Medical Device Packaging, SBS Box Partitions for Medical Device Packaging, Solid Bleach Sulfate Box Partition Uses